Commercial

-

Alderman’s Toyota

Alderman’s Toyota

-

The Automaster

The Automaster

-

The Automaster Honda and Mercedes-Benz

The Automaster Honda and Mercedes-Benz

-

Best Tile

Best Tile

-

Carbone Auto Group

Carbone Auto Group

-

Dinse, Knapp & McAndrew

Dinse, Knapp & McAndrew

-

Middlebury Natural Foods Co-op

Middlebury Natural Foods Co-op

-

National Bank of Middlebury

National Bank of Middlebury

-

Orvis - Corporate Headquarters

Orvis - Corporate Headquarters

-

Orvis - Retail Flagship

Orvis - Retail Flagship

-

People’s United Bank

People’s United Bank

-

The Automaster

The Automaster

-

Vermont Country Store

Vermont Country Store

-

Vermont School Board Insurance Trust Office

Vermont School Board Insurance Trust Office

Cultural

-

Bennington Museum

Bennington Museum

-

Camp Dudley at Kiniya

Camp Dudley at Kiniya

-

Camp Kiniya Bath House

Camp Kiniya Bath House

-

Fort Ticonderoga

Fort Ticonderoga

-

Montshire Museum of Science

Montshire Museum of Science

-

Northern Stage

Northern Stage

-

Riley Rink at Hunter Park

Riley Rink at Hunter Park

-

Southern Vermont Arts Center - Arkell Pavilion and Yester House Gallery

Southern Vermont Arts Center - Arkell Pavilion and Yester House Gallery

-

St. James

St. James

-

Town Hall Theater

Town Hall Theater

-

Town of Manchester Park House

Town of Manchester Park House

-

Town of Stowe Ice Arena

Town of Stowe Ice Arena

-

Weston Playhouse Theatre Company

Weston Playhouse Theatre Company

Education

-

Dartmouth College - Tennis Center

Dartmouth College - Tennis Center

-

Hugh J. Gallen Career and Technical Center & Middle School

Hugh J. Gallen Career and Technical Center & Middle School

-

Landmark College

Landmark College

-

Landmark College - Click Sports Center

Landmark College - Click Sports Center

-

Landmark College - East Academic Building

Landmark College - East Academic Building

-

Landmark College - Student Residences

Landmark College - Student Residences

-

Northfield Mount Hermon Faculty Housing

Northfield Mount Hermon Faculty Housing

-

Northfield Mount Hermon School

Northfield Mount Hermon School

-

The Greenwood School Academic Center

The Greenwood School Academic Center

-

The Greenwood School

The Greenwood School

-

University of Vermont

University of Vermont

-

University of Vermont – Harris–Millis Commons

University of Vermont – Harris–Millis Commons

-

University of Vermont - McAuley Hall

University of Vermont - McAuley Hall

-

University of Vermont

University of Vermont

-

Vermont Academy Fuller Hall

Vermont Academy Fuller Hall

-

Vermont Technical College

Vermont Technical College

-

Williams College - Student Center

Williams College - Student Center

Healthcare

Hospitality

Manufacturing

Municipal

-

Town of Antrim Police Station

Town of Antrim Police Station

-

Ferrisburgh Grange Hall

Ferrisburgh Grange Hall

-

Town of Hartford

Town of Hartford

-

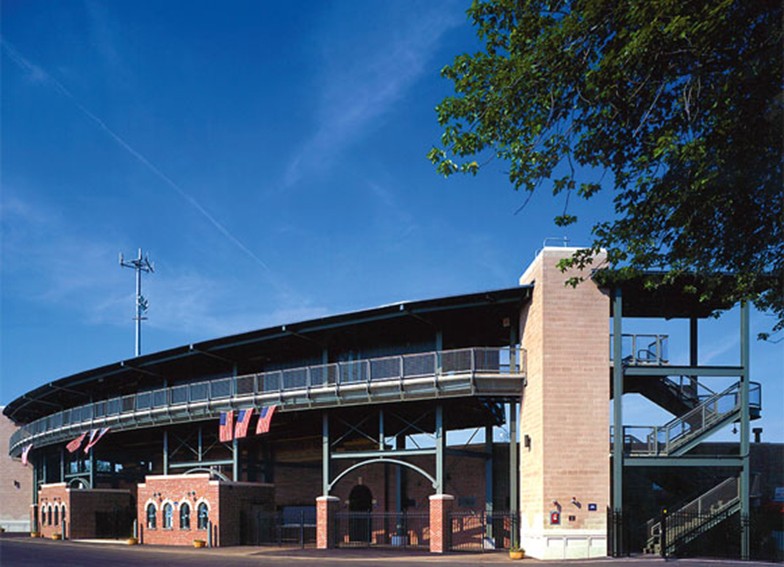

Holman Stadium

Holman Stadium

-

Lebanon Veteran’s Memorial Pool

Lebanon Veteran’s Memorial Pool

-

Mahady Courthouse

Mahady Courthouse

-

Middlebury Police Station

Middlebury Police Station

-

North Country SPCA Animal Shelter

North Country SPCA Animal Shelter

-

Town of Colchester Police Station

Town of Colchester Police Station

-

Town of Middlebury Fire Department

Town of Middlebury Fire Department

-

Town of Middlebury

Town of Middlebury

-

Town of Middlebury

Town of Middlebury

-

Town of Stowe

Town of Stowe

-

City of Vergennes Police Station

City of Vergennes Police Station

-

Williston Police and Fire Stations

Williston Police and Fire Stations

Hypertherm Heater Road

Manufacturing Facility

When Hypertherm was choosing a design build partner to design and construct our new 160,000 SF manufacturing plant in Lebanon, NH, Bread Loaf Corporation appeared to be the logical choice. During the interviews Bread Loaf talked about their innovation, robust design and building processes, problem solving, cost control, and customer satisfaction. We needed these skill sets in our partner for the project to be successful. After completing a very complex yet LEED certified manufacturing project, I can say Bread Loaf not only met these expectations but exceeded them. They knocked this one out of the park. Hypertherm is a very pleased customer.

Summary

Hypertherm, Inc. of Lebanon, New Hampshire is the world leader in plasma metal cutting technology. Bread Loaf Corporation provided Planning, Design and Construction services for their new Heater Road facility, includes 156,500 square foot of manufacturing, research laboratory and office space. Hypertherm’s main manufacturing plant and headquarters at Great Hollow Road and the new Heater Road facility will form bookends along a corridor of smaller Hypertherm sites to support their growing operations.

The development of their previously altered site included preservation of six acres of wetlands and use of sustainable landscape design strategies including pervious pavement and rain-gardens to filter storm water. The building is designed to achieve functional flexibility, to promote a healthy workplace and to measure and optimize energy use and efficiency.

The project was awarded LEED Gold certification by the USGBC.

Green Building/Sustainable Design

- Stormwater quality controlled using raingardens, bioswales and pervious pavement

- Reduction of energy use with efficient LED site lighting

- Light material to limit heat island effect of roof surface

- 40% reduction in water use through low flow fixtures

- 100% recycling of process water used for product testing

- 14% reduction in over-all energy demand

- Energy reductions through enhanced commissioning

- Measurement and verification plan for building systems

- 20% of building materials contained a high recycled content

- 10% of building materials were regionally sourced materials

- 75% of the construction waste materials were recycled or salvaged

- Low-emitting adhesives, paints and materials

- Skylights to provide daylighting in manufacturing areas

- Solar panels for domestic hot water